Name of Beneficiary: OOO Nano Prime

Total cost of the project (total for all beneficiaries): PLN 11,659,025.90.

Financing: PLN 6,995,415.54.

Project Description:

OOO Nano Prime received EU funding for the project “Development of technology and commissioning of the production of innovative dental implants with increased osteoinductive properties.” The goal of this project is to develop a technology for the production of innovative dental implants. It would seem that in connection with the modification of the surface of titanium dental implants, everything has already been done. However, there is always the problem of insufficient osseointegration of implants with the bone or their rejection by the body, especially several years after implantation. Our company decided to develop an innovative method for modifying the surface of implants, as well as build a prototype installation for their production. Within the framework of the project, the most important key stages of implant processing for us are the initial surface preparation (machining, polishing, etching), and above all, the final processing - the plasma electrochemical oxidation (PEO) process. Through the initial processing we obtain the appropriate development of the surface of the dental implants, during the PEO process we produce a ceramic oxide layer to obtain excellent adhesion to titanium. Very importantly, the PEO process enriches the oxide layer with electrolyte components, therefore the chemical composition of the electrolyte is designed in such a way that on the surface of dental implants there is a layer containing calcium and phosphorus with the appropriate atomic ratio. This modified implant surface causes crystallization of hydroxyapatite (a mineral component of bone) and also increases the rate of proliferation of osteoblastic cells. As a result, the developed implant grows faster to the bone and at the same time is loaded faster. We are currently collecting certificates to register the implants and obtain the CE mark. The main subcontractor that supports Nano Prime Ltd. in the implementation of the project is the Faculty of Chemistry of the Silesian University of Technology in Gliwice.

Dental implant with BioTiCer surface:

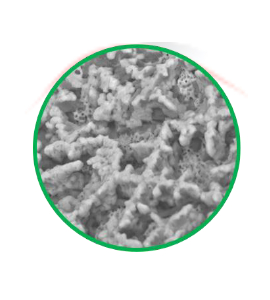

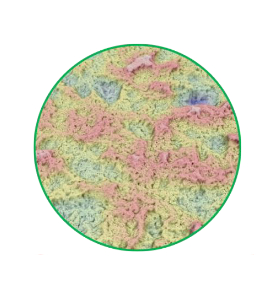

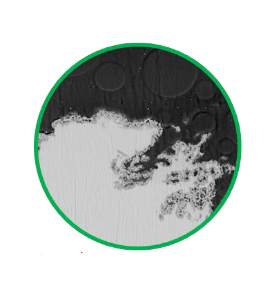

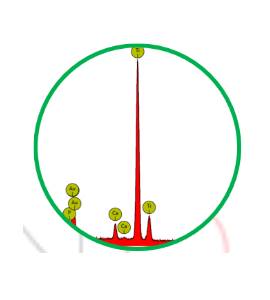

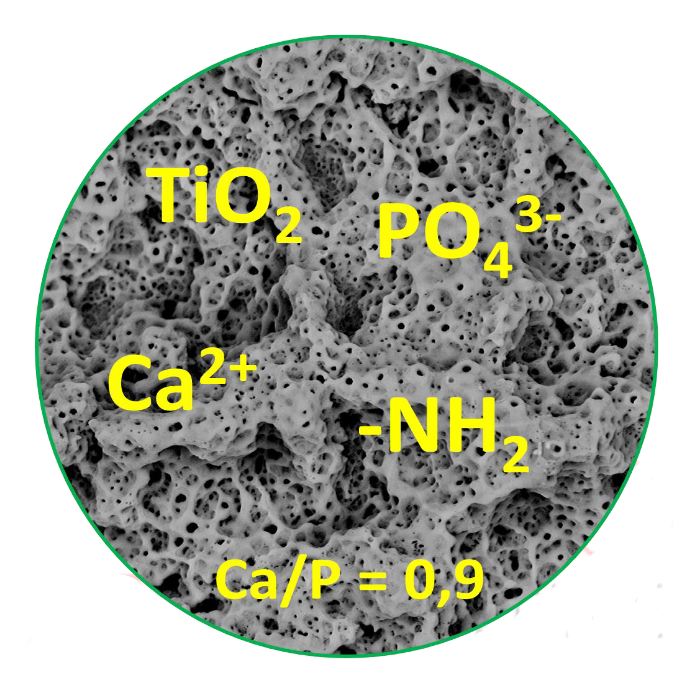

One of the most important elements that influences the proper fusion of a dental implant with the bone is its surface. It is the one that comes into contact with the bone during implantation. Surface properties affect the rate of adsorption of water, proteins, blood components, as well as cells and their subsequent reproduction. To improve the biological properties of titanium implants, NanoPrime has developed a surface modification process based on high voltage electrochemical oxidation. This process in English is called plasma electrolytic oxidation (PEO) or micro-arc oxidation (MAO). During the PEO process, a dielectric oxide layer is formed on the surface of the titanium implant. Due to the high voltage used in this process, this layer breaks through and produces a distinctive nano- and microporous surface structure. The resulting layer is uniform over the entire surface of the implant. The average roughness coefficient is 1.75 m. The advantage of the PEO process is the ability to apply layers to products that have a complex shape, such as dental implants. This layer adheres perfectly to the material (titanium) and has an average thickness of 3m. The next advantage of the PEO process is the ability to include any electrolyte components in the created layer. The PEO process used by Nano Prime is designed so that the resulting titanium oxide (anatase) layer is enriched with biocompatible calcium and phosphorus, as well as amino groups. The concentration of calcium and phosphorus is selected so as not to change the mechanical properties of the TiO2 produced. Calcium and phosphorus present in the oxide layer appear in the form of calcium phosphate (in the entire volume of TiO2 produced). The atomic ratio of calcium to phosphorus is about 0.9. Due to this, rapid crystallization of calcium phosphates, primarily hydroxyapatite, occurs on the surface of titanium implants. In addition, the presence of Ca and P, as well as amino groups, has a very positive effect on the proliferation of osteoblasts and osseointegration of the implant.at.

SEM image of the surface of a Nano Prime implant with BioTiCer surface

3D image of the Nano Prime implant surface with BioTiCer surface

Cross-section of a Nano Prime implant with BioTiCer surface

Cross-section of a Nano Prime implant with BioTiCer surface

Hydroxyapatite crystallized on the surface of the Nano Prime implant with BioTiCera surface after testing in a simulated solution of human blood plasma (SBF)

Nano Prime with BioTiCer surface

Even during the coronavirus pandemic, Nano Prime tried to demonstrate the progress of its research and development work.

04-Jan-2024